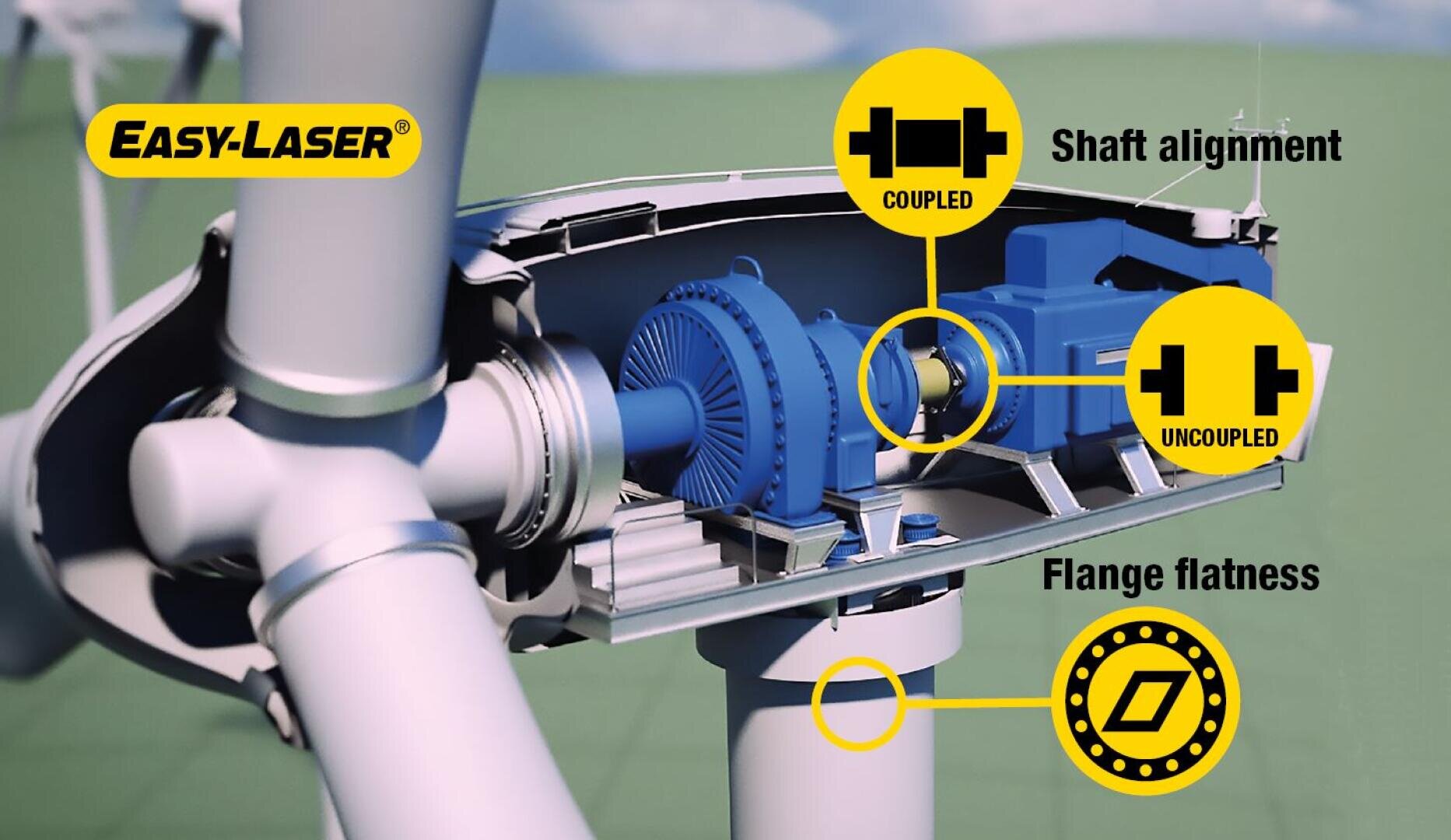

Alignment solutions for the wind power industry

For a wind turbine to operate reliably and efficient, laser alignment is crucial. Both for shaft/coupling alignment at the generator and gearbox, and flatness measurement of tower flanges when sections are manufactured.

Our customers are some of the world's largest manufacturers of wind turbines internationally. We also supply the maintenance companies servicing turbines at wind farms, and the workshops manufacturing tower sections. They all need tools they can rely on.

Shaft alignment solutions

Standard shaft alignment systems or specially adapted OEM variants are available. The latter are designed to fit a turbine manufacturer's specific dimensions of the couplings on a large number of turbine variants in their range. They are designed to be used with the coupling removed and the rotor locked, as this is the safest for the operator when working high up in the nacelle.

Easy-Laser's standard system is used on other coupling designs and where it is considered safe to leave the coupling in place. They are intended both for installation and for continuous maintenance work in the field, and are therefore well suited to the requirements of service companies.

Flatness measurement of flanges

Flanges always need to be flat within specified tolerances. If flatness measurement of the flanges is difficult depends, among other things, on the diameter of the tower. Smaller diameters (up to 4 meters) are usually straightforward to measure. But large diameters, especially large offshore towers, require a different approach. Easy-Laser has solutions that makes measurement easy and precise.